Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

The past week has seen headlines across the globe echo an accelerating shift: electric vehicles (EVs) are no longer a niche segment but an industry‑wide tectonic plate. In the United States, the U.S. Department of Transportation announced that EV sales rose 22% in the first quarter of 2025, while the European Commission unveiled its “Fit for 55” roadmap that commits the EU to phase out internal‑combustion cars by 2035. China, the world’s largest EV market, reported a record 3.2 million EV deliveries in March alone, surpassing all conventional vehicle sales in a single month. These milestones are not just numbers; they are the manifestation of a worldwide strategy to decarbonise transport, boost local manufacturing, and secure supply chains of critical components.

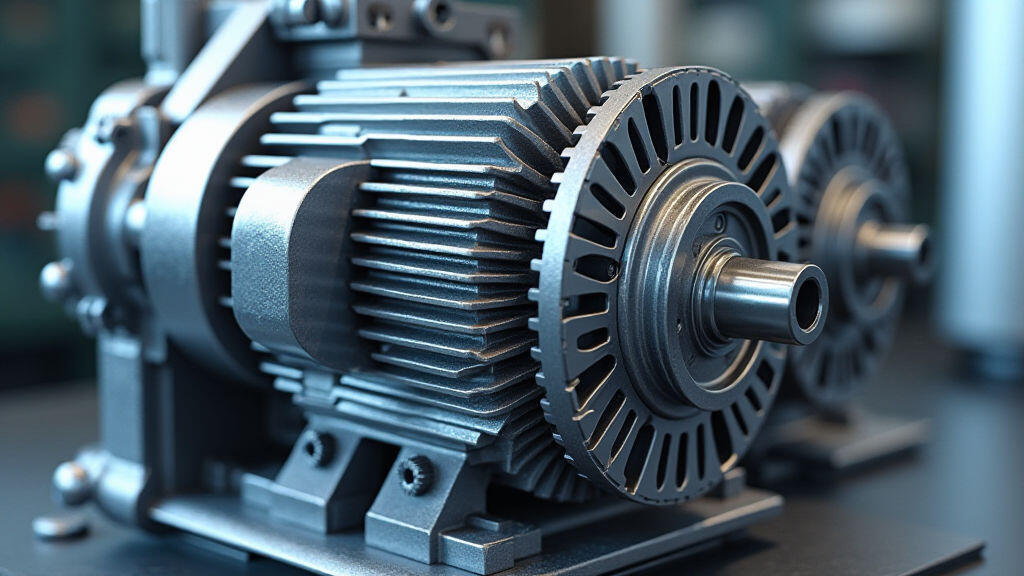

Amid this surge, one unsung hero plays a pivotal role: the gear or reducer motor. While consumers focus on sleek designs, cutting‑edge batteries, and autonomous driving, behind the scenes a compact, efficient gearbox–motor unit is quietly propelling vehicles forward.

Every EV requires a motor that can deliver high torque at low speeds while keeping heat—our biggest constraints—under control. Traditional drivetrains used a separate high‑speed motor (>10,000 rpm) and an external gearbox to reduce speed and increase torque. This results in a bulky, noisy, and heat‑intensive assembly. As orders surged, both EV makers and component suppliers realised that packable, integrated solutions were essential to meeting the aggressive volume and weight targets set by governments and consumers.

Gear motors combine a motor and a gearbox into one hermetically sealed unit. Designed for the 5,000–10,000‑rpm range typical of electric cars, they deliver the torque needed for acceleration while keeping the overall weight down. The result? Volkswagen’s new “MEB” platform achieved a 30% reduction in drive‑train weight, partly thanks to these compact motor‑gear assemblies.

Recent breakthroughs in materials and electronics have elevated gear motors to a new generation. These improvements revolve around three core dimensions:

These innovations directly align with EV manufacturers’ relentless push to thin the floor and climb to higher efficiency ceilings—an imperative amplified by the high carbon footprints associated with battery production.

Take Tesla’s new “4680” battery cells, for example. The high energy density of these cells imposes stricter weight and thermal envelopes for the accompanying drive system. Tesla’s in‑house design team chose gear motors for their compactness and integration capability, allowing the Model 3’s core to stay aerodynamic while the motor’s efficient torque curve accelerates the car swiftly from 0–100 km/h in 4.5 seconds.

Moreover, emerging “single‑motor” EVs—vehicles powered by one motor that distributes torque to all four wheels via a mechanical actuator—rely heavily on accurate gear‑motor control. The synergy of precise motor positioning and a well‑matched gearbox ensures reliable torque delivery and optimal regenerative braking efficiency.

Looking ahead, several trends hint at deeper integration of gear motors within EV ecosystems:

These directions suggest a future in which gear motors are not merely components but can be seen as “city‑level power hubs” that adapt in real time to traffic patterns, charging demand, and renewable energy availability.

The world’s media buzz is about EVs making pareto‑shifts in transportation, but the essential message remains simple: for the ever‑expanding electric vehicle market to achieve mass adoption, every millimeter, every gram, and every watt must be optimised. Gear motors—compact, efficient, and thematically aligned with the green transition—are the secret sauce that allows automakers to hit targets for range, cost, and sustainability.

As governments worldwide push for zero‑emission fleets and manufacturers compete to deliver the next flagship model, industries that supply reliable, high‑performance gear motors will find themselves at the centre of this transformational wave. The next decade is bound to see more electric cars, buses, and even personal urban vehicles turning the same silent yet powerful gear motor into a watchword for progress.

Leave A Reply

Your email address will not be published. Required fiels are marked